Witron COM Picks Up 1000th Order

11th June 2019

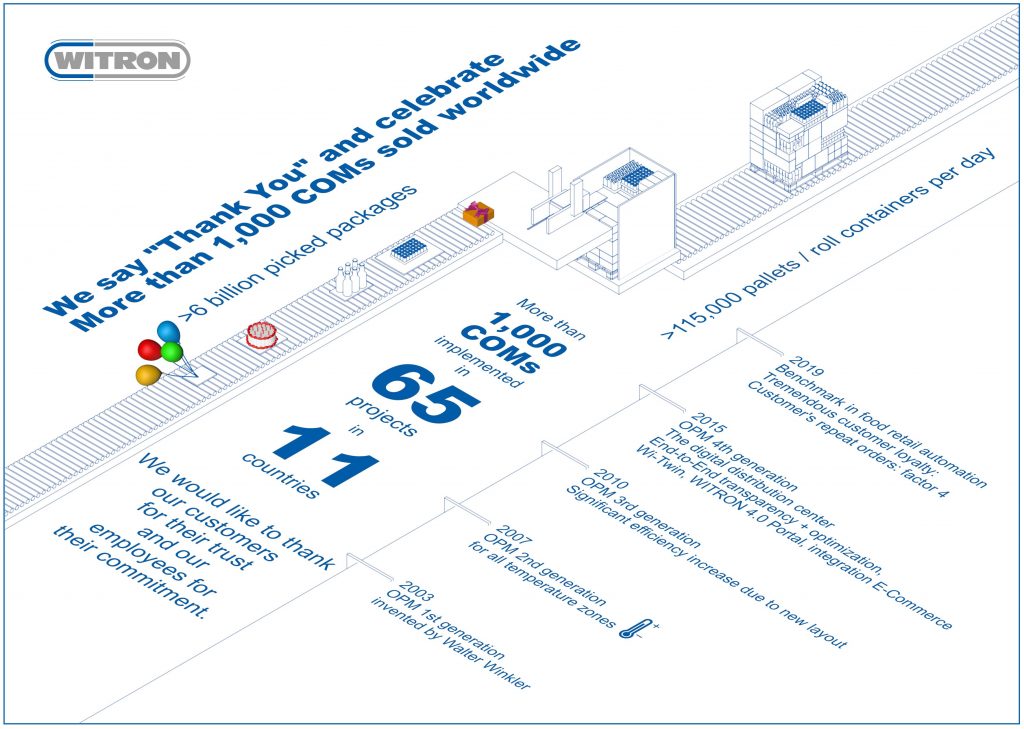

Intralogistics specialist Witron has had its 1000th order for its breakthrough Case Order Machine (COM), which it first brought to the Order Picking arena in 2003. It was an invention of the company founder, Walter Winkler.

Following customer demand, Witron developed the OPM system in 2003, which has since set standards as a model for robotic solutions in logistics at a time when, the company says, hardly any logistics expert or manufacturer talked about robots in the warehouse. Over the years, the system has been continuously improved and adapted to customer requirements.

In the fourth generation, which is being integrated since 2015, the focus is on the integration of E-Commerce processes, the digitalization of processes, their simulation with a digital twin and the collection and analysis of data as a decisive factor for the operator. “13 years ago, we presented – for the first time – integrated automation from receiving down to dispatch,” recalls Helmut Prieschenk, CEO of Witron. Today, more than 115,000 pallets are stacked with the OPM system per day. “We would like to thank our customers for their trust and our employees for their commitment.”

The OPM is successfully used for order picking in dry goods assortment, and in the fresh food and frozen goods sector. The OPM technology generates significant advantages along the entire supply chain. Starting with benefits within the distribution centres (high cost-efficiency and ergonomics), optimisation during transportation (up to 20% more densely packed pallets or roll containers), through to synergies in the supermarket (store-friendly to pick). Due to the modularity and flexibility of the picking system it is possible to use this technology cost-efficiently in almost all warehouse sizes without any problems – no matter if the user handles 15,000 or more than 400,000 cases per day in the distribution Centre – and regardless of whether the product range consists of 300 SKUs or far more than 10,000 SKUs.